The benefits of an automatic lubrication system.

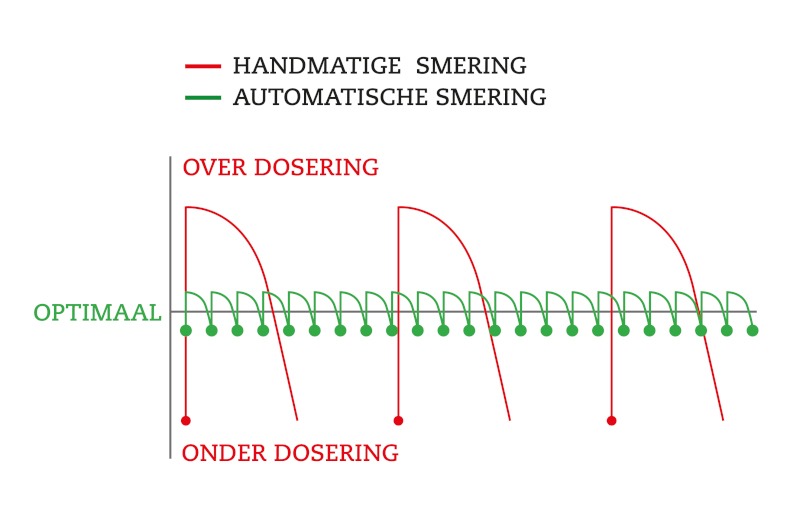

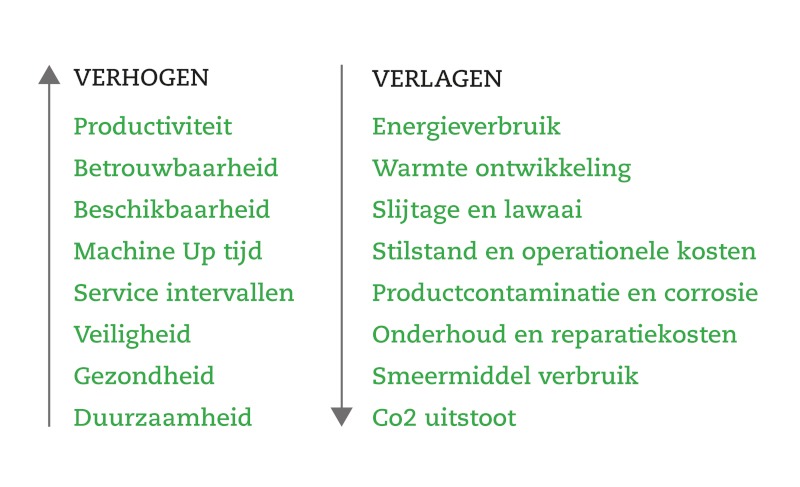

Automatic lubrication provides an optimal amount of lubrication in a consistent manner. This way machines last longer, productivity is higher, the production line is more reliable and costs are saved. In addition, work can be done more safely.

- It increases safety because there is no longer any need for manual lubrication during production.

- It improves the service life of mechanical components and machines.

- Profit from improved productivity.

- Cost reduction by avoiding unplanned downtime or unplanned maintenance.

- Friendly to people and the environment due to metered lubrication without waste.

- Reduction of packaging material.

Possibilities automatic and central lubrication

There are various options and principles for automatic and central lubrication. For example, Lincoln Quicklub lubrication systems. Lincoln "Quicklub" is the collective name for all lubrication systems and components of the progressive principle. Progressive stands for correct dosing of each lubrication point through pre-set volumes of the distributors. Controllable at various levels. Click here for a video presentation.

The Quicklub line consists of:

Grease pumps 24V model P502, P203, and QLS

Grease pumps 230V model P203 and QLS

Grease pumps 12V model P502, P203, and QLS

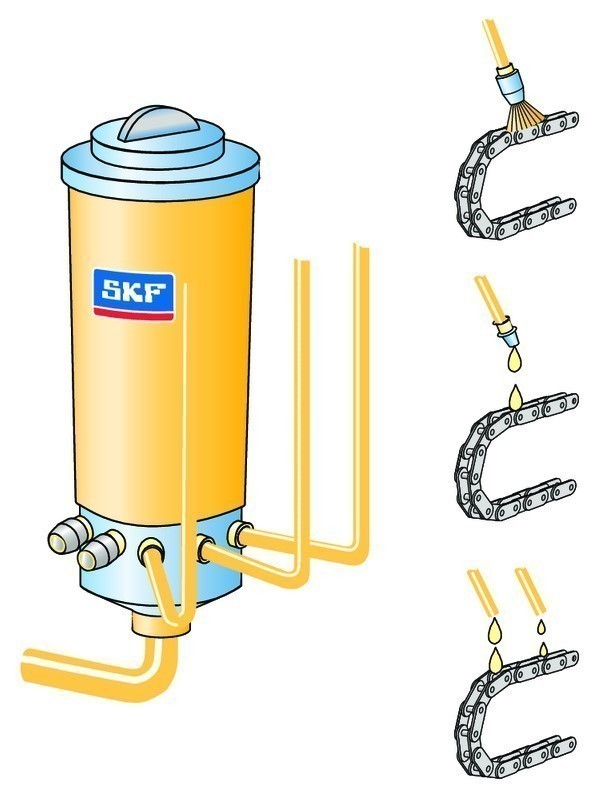

Automatic chain lubrication

Despite new materials and advanced technologies, many chains still require lubrication. Optimal lubrication reduces friction and thus any wear. The greatest relative movement takes place between the plates, pins and rollers. These are also the points where the most forces are exerted on the chain.

Insufficient lubrication of this area will lead to premature wear and failure, resulting in production stops and the associated high costs. Correct and efficient lubrication is a prerequisite for trouble-free operation and a long service life of the chain. Lincoln automatic chain lubrication systems deliver a precisely measured amount of lubricant, where it is needed for optimal lubrication. Every chain drive is unique, so we advise you to contact us for sound advice.

Ancotech has the solution for the most common questions. Whether it concerns bearings, chains, gears, rollers or slides, there is a solution for everything. We are always ready to give advice. Call us +31 (0) 72-561 65 53 or mail to: [email protected]